Nā huahana

Pahu kila PE no ke kinoea

Palapala noi

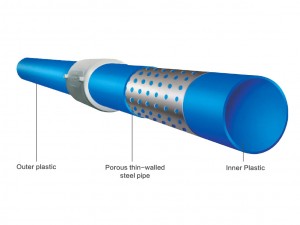

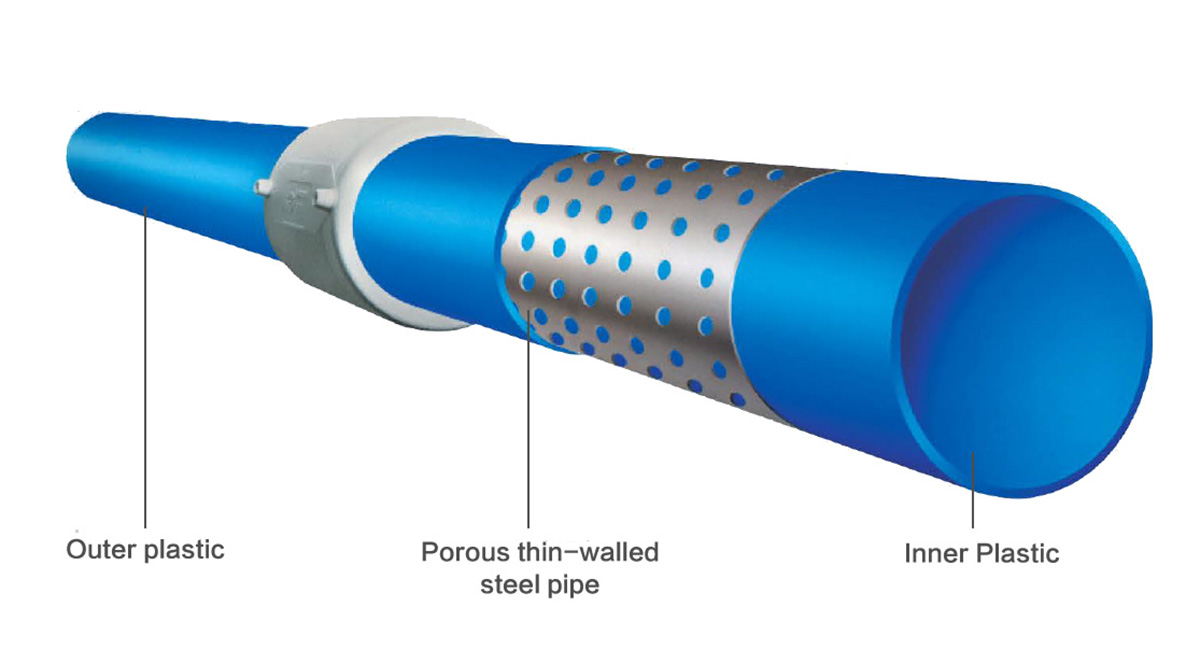

Hana ʻia ka paipu huikau polyethylene i hoʻopaʻa ʻia me ke kila ʻōwili anuanu a me nā thermoplastics ma ke ʻano he mea maka, a ʻo nā paipu kila lahilahi ʻeleʻele i hana ʻia e ka argon arc butt welding a i ʻole plasma spiral welding e hoʻohana ʻia i mea hoʻoikaika. ʻO ka ʻaoʻao o waho a me loko he thermoplastics composite ʻelua ʻaoʻao. ʻO kahi ʻano hou o ka paipu puʻupuʻu composite, No ka mea ua hoʻopaʻa ʻia ka paipu porous i hoʻopaʻa ʻia i ka thermoplastic mau, ʻaʻole i lanakila wale kēia paipu hui i nā hemahema o nā paipu kila a me nā paipu plastik, akā loaʻa nō hoʻi ka rigidity o nā paipu kila a me ka corrosion. kū'ē o nā paipu plastik. He hopena ia no nā ʻoihana ʻaila a me nā kemika. He pipeline koi nui ia o nā paipu paʻa nui a me ke anawaena ma nā kahua o ka lāʻau lapaʻau, ka meaʻai, ka mining, ke kinoea a me nā māla ʻē aʻe. He mea hoʻokō ʻenehana hoʻololi hoʻi ia e hoʻoponopono i ka pipeline nui o ke kūkulu ʻana a me ka lako wai kūloko. He ʻano hou ia o ka pipeline composite i ka 21stkenekulia.

Nā hiʻohiʻona

Hana maʻemaʻe

ʻO ka papa kuhikuhi maʻemaʻe a me ka palekana o ka pipe perforated steel strip plastic composite pipe e hoʻokō i nā koi o GB9687 "Hygienic Standard for Polyethylene Molded Products for Food Packaging" a me GВ/Т17219 "Safety Evaluation Standard for Drinking Water Distribution Equipment and on Equipment and Protective Materials". ʻO ia ka mea pani maikaʻi loa no ka paipu galvanized a me ka paipu hao.

Paheʻe i loko o ka pā a me ka hana kaʻapuni

ʻO ka paia o loko o ka mesh steel belt plastic composite pipe he maʻalahi loa, a ʻo ka roughness loa he 1/20 wale nō o ka paipu kila. ʻO ka hiki ke lawe ma lalo o nā kūlana like ma kahi o 30% kiʻekiʻe ma mua o ka paipu kila.

Nā ʻāpana ʻenehana

| ʻO ka nui kikoʻī, ka hoʻokaʻawale ʻana a me ke kaomi nominal: e hoʻokō i nā koi o ke Kuhina o ke kūkulu hale maʻamau CJ/T181-2003 | |||||

| Nominal waho anawaena a me ka deviation | Nominal pā mānoanoa a me ka deviation | No ka poepoe | Pumi inoa | Waiwai S liʻiliʻi loa | Ka lōʻihi a me ka hoʻokaʻawale |

| Dn(mm) | En(mm) | Mm | Mpa | Mm | mm |

| 50+0.5 0 | 4.0+0.5 9 | 1.0 | 1.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5+0.6 0 | 1.26 | 1.0 | 1.5 | |

| 75+0.7 0 | 5.0+0.7 0 | 1.5 | 1.0 | 1.5 | |

| 90+0.9 0 | 5.5+0.8 0 | 1.8 | 1.0 | 1.5 | |

| 110+1.0 0 | 6.0+0.9 0 | 2.2 | 1.0 | 1.5 | |

| 140+1.1 0 | 8.0+1.0 0 | 2.8 | 1.0 | 2.5 | |

| 160+1.2 0 | 10.0+1.1 0 | 3.2 | 1.0 | 2.5 | |

| 200+1.3 0 | 11.0+1.2 0 | 4.0 | 1.0 | 2.5 | |

| 250+1.4 0 | 12.0+1.3 0 | 5.0 | 0.8 | 3.5 | |

| 315+1.6 0 | 13.0+1.4 0 | 6.3 | 0.8 | 3.5 | |

| 400+1.6 0 | 15.0+1.5 0 | 8.0 | 0.8 | 3.5 | |

| 500+1.7 0 | 16.0+1.6 0 | 10.0 | 0.6 | 4.0 | |

| 630+1.8 0 | 17.0+1.7 0 | 12.3 | 0.6 | 4.0 | |

| 'Ōlelo Aʻo: ʻO ke kaomi nominal o ka paipu composite ka nui o ke kaomi i ʻae ʻia no ka paipu e lawe i ka wai ma 20 ° C. Inā hoʻololi ka mahana, pono e hoʻoponopono ʻia ke kaomi hana e like me ka coefficient kaomi wela o nā mea like ʻole. S waiwai: ka mamao mai ke anawaena o waho o ka hoʻoikaika i ka ʻili o waho o ka paipu. | |||||

| Nā koi hana kino a me ka mechanical | ||

| Papahana | hana | |

| 'Oolea apo, KN/m2 | >8 | |

| Hoʻemi lōʻihi (110°C, mālama 1h) | <0.3% | |

| Hoʻāʻo hydraulic | Mahana: 20°C; Manawa: 1h; Pumi inoa x2 | ʻAʻole i haki |

| Mahana: 80 ° C; Manawa: 165h; Pumi: Pumi inoa x2x0.71 (helu ho'ēmi) | ||

| ʻO ka hoʻāʻo ʻana i ke kaomi ʻūhā | Mahana: 20°C, puʻe pahū≥nominal kaomi x3.0 | Pahū ʻana |

| Ka manawa induction oxidation (200 ° C), min | >20 | |

| Kū'ē i ka hoʻonui kaumaha wikiwiki (80 ° С, 4.0Mpa) / h | >1000 | |

| Ke kū'ē i ka wā (ma hope o ka loaʻa ʻana o ka paipu≥3.5GJ/m2ikehu kahiko) | E hoʻokō i nā koi o nā mea 2,3 a me 4 i kēia pākaukau, a hiki ke mālama i ka hana kuʻi maikaʻi | |